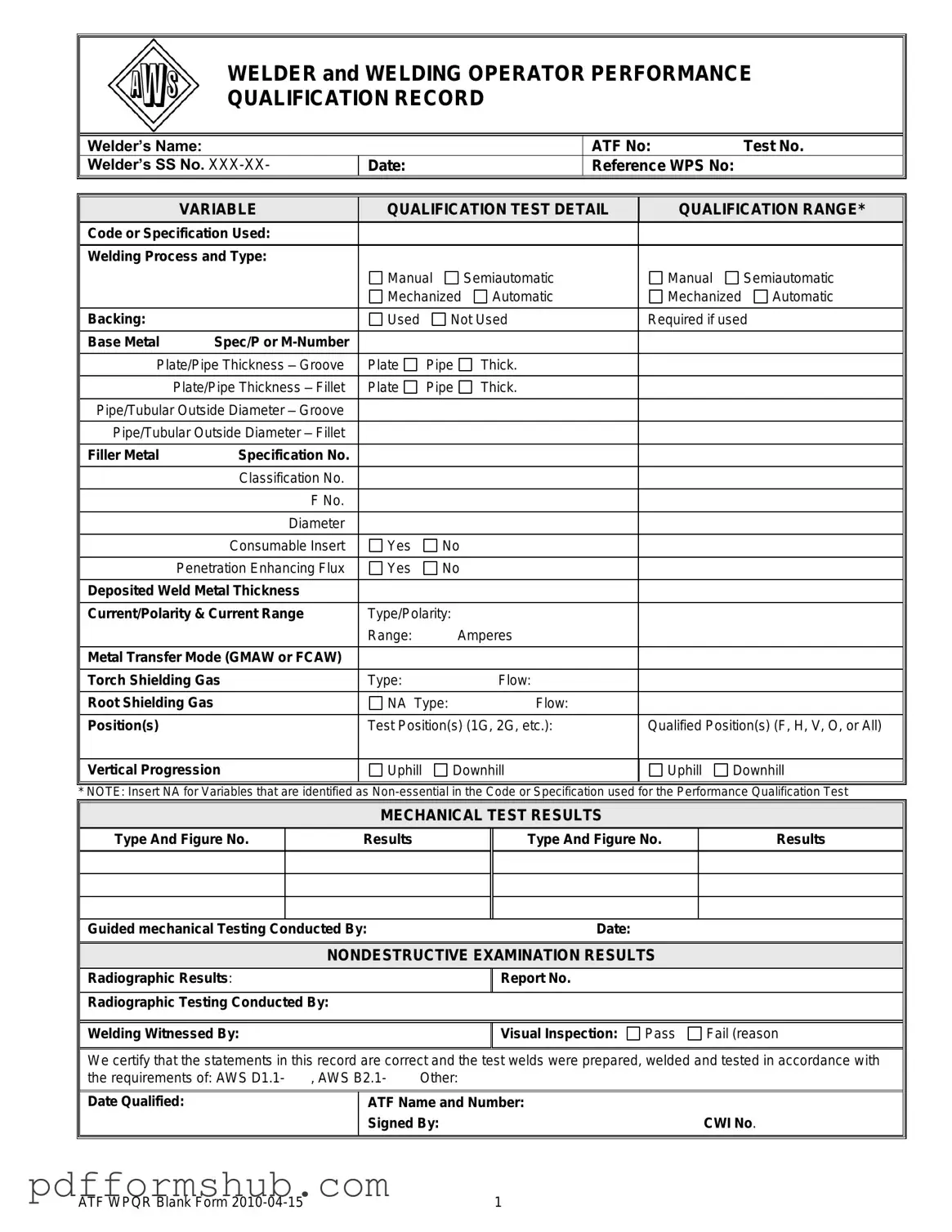

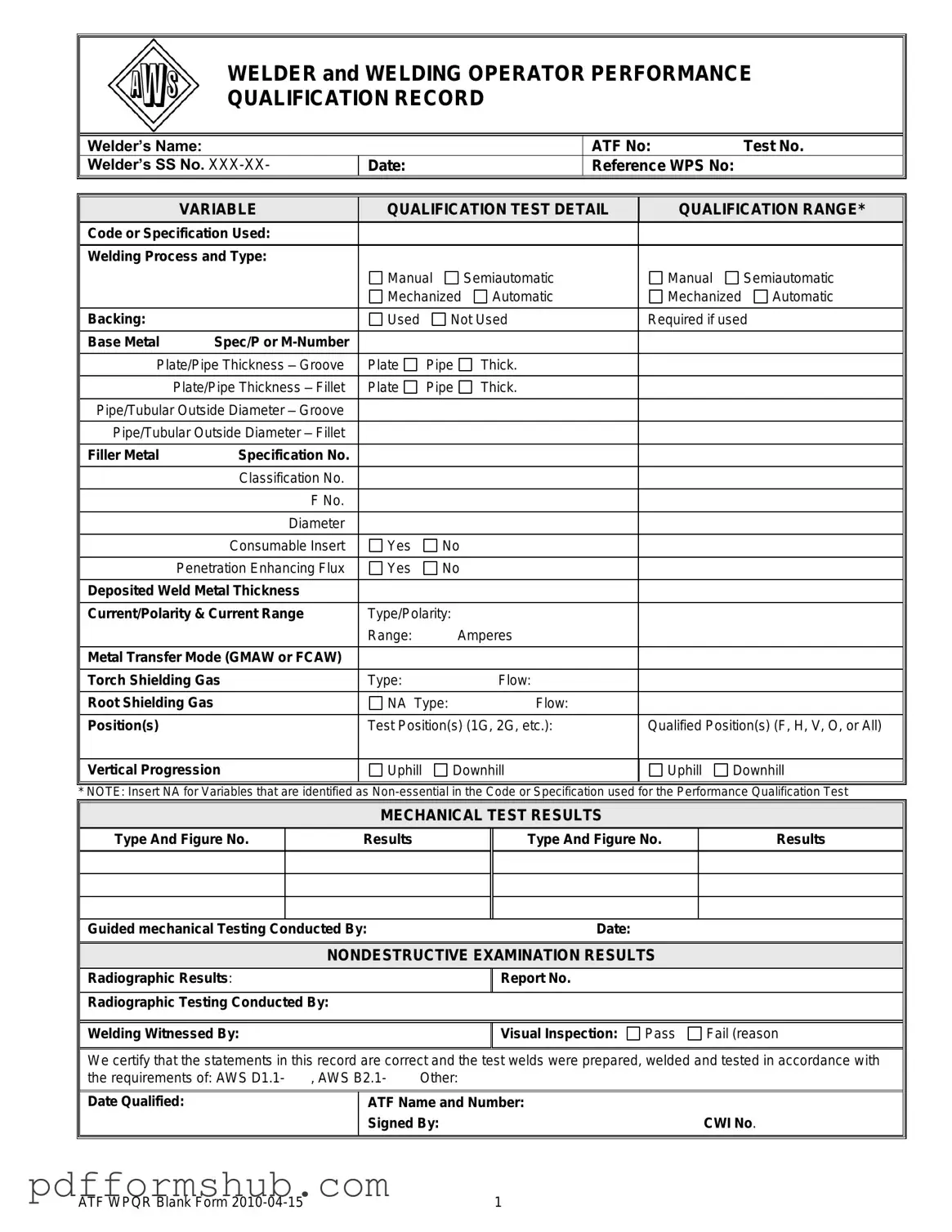

Fill in Your Welder Performance Qualification Record Form

The Welder Performance Qualification Record form is a critical document used to verify a welder's skills and capabilities in various welding processes. It includes essential details such as the welder's name, test results, and specifications related to the welding performed. Completing this form accurately is vital for ensuring compliance with industry standards and maintaining safety protocols.

To begin filling out the form, please click the button below.

Customize Form

Fill in Your Welder Performance Qualification Record Form

Customize Form

Customize Form

or

Free PDF Form

Short deadline? Complete this form now

Complete Welder Performance Qualification Record online without printing hassles.