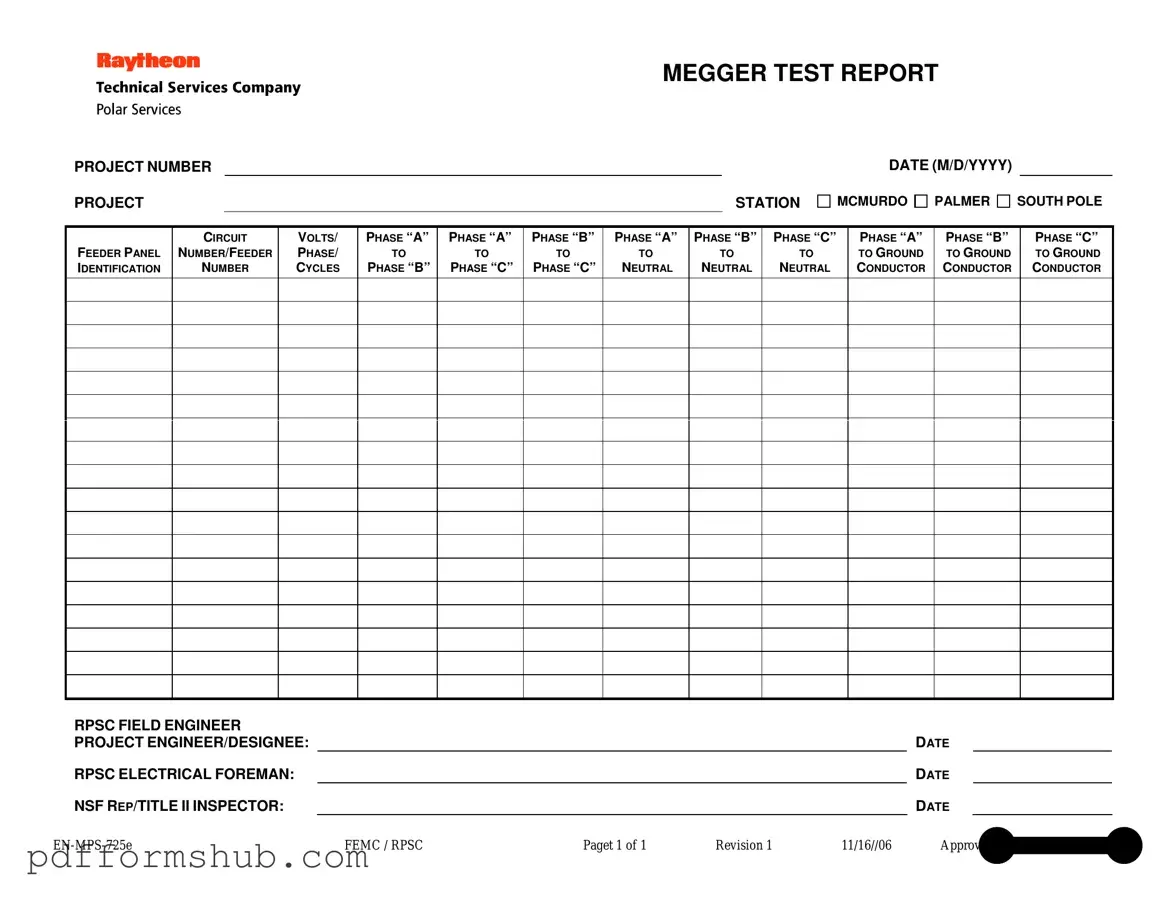

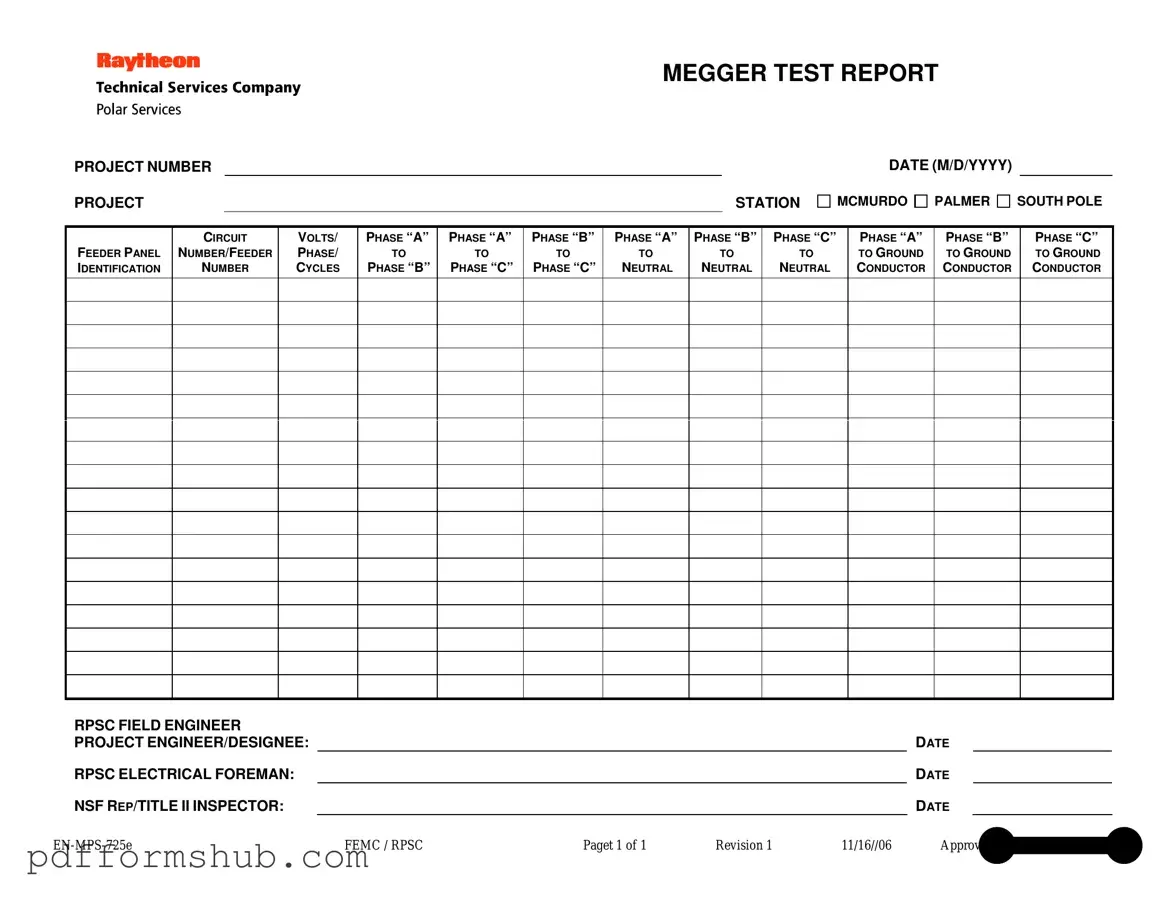

Fill in Your Megger Test Form

The Megger Test form is a critical document used to record the results of insulation resistance testing on electrical systems. This form captures essential data such as project identification, voltage levels, and test results for various phases and conductors. To ensure accuracy and compliance, it's important to fill out this form correctly; you can get started by clicking the button below.

Customize Form

Fill in Your Megger Test Form

Customize Form

Customize Form

or

Free PDF Form

Short deadline? Complete this form now

Complete Megger Test online without printing hassles.